Executive Masterclasses for Operational Performance

The Future Factory delivers high-impact, transformational training for business leaders developing world-class, sustainable operations across manufacturing, supply chain, innovation, and AI.

Executive Training for leaders across Operational Excellence, Supply Chain, Digital Transformation, and AI

Join 2,500+ Senior Executives

Gain exclusive access to our world-class executive training. Join 2,500+ senior professionals in high-impact Masterclasses and strategic advisory programmes, shaping the future of leadership, AI, digital transformation, innovation, and operational excellence.

“This Masterclass was very good, providing a broad overview on digital transformation, from a business, organisational, technology and change management perspective.”

President & Deputy Chief Executive Officer, Nestlé Nespresso

Future-Focused

Leadership Training.

Real-World Results. Transformative Impact.

As a premier provider of executive training, we equip organisations with the expertise to harness AI, operational excellence, and innovation for sustained success. Our world-class programmes, trusted by global industry leaders, empower executives with the skills to navigate disruption, optimise operations, and drive customer-centric growth with measurable impact.

Join a global network of industry innovators

Our members are trailblazers, innovators, and disruptors, leveraging digital tools, strategies, and processes to transform their organisations, sustain a competitive edge, and excel in a technology-driven, carbon-neutral world.

Joining our cross-industry, global network provides access to meaningful connections with senior leaders and industry pioneers, offering valuable opportunities to exchange ideas and insights. You’ll stay ahead of emerging trends in digital transformation and innovation while learning from experienced practitioners across diverse sectors.

As a member, you’ll receive tailored updates on learning and development programmes designed to elevate your leadership and empower your teams to drive sustainable growth. Request membership today and unlock access to a world of opportunity.

“A chance to understand and explore new digital technologies.”

Head of Digital Culture, Rolls-Royce

Empowering Leaders. Accelerating Innovation. Transforming Organisations.

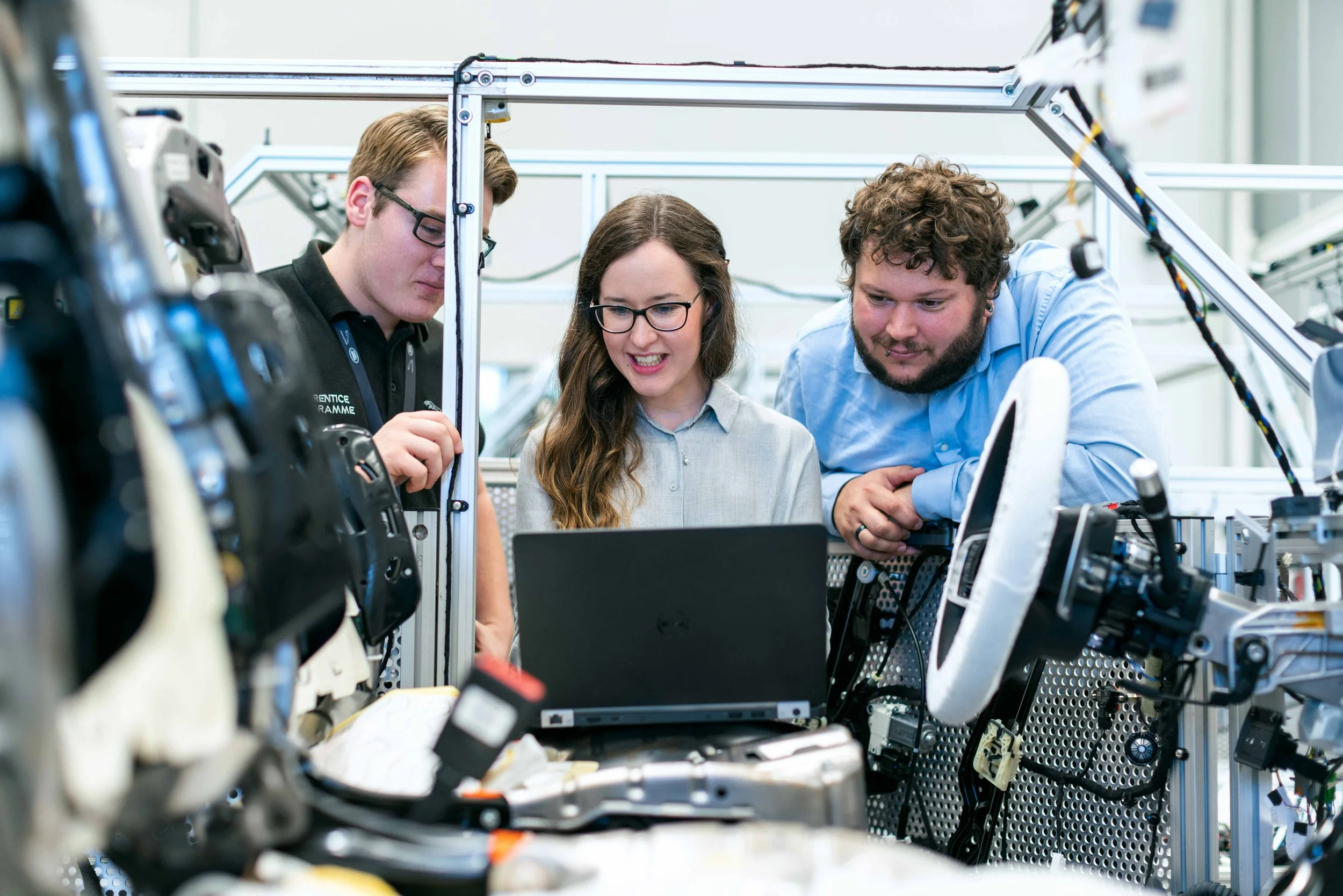

We partner with forward-thinking organisations to design and deliver transformational training that drives measurable results. At our core, we believe in building future-ready leaders equipped with the skills to navigate today’s complex and ever-evolving landscape.

Our bespoke solutions and open training programmes are tailored to address your unique challenges, empowering teams to unlock their full potential. From executive coaching to immersive workshops, we help businesses achieve sustainable growth by fostering leadership excellence and innovation.

With a blend of strategic insight, hands-on experience, and a relentless focus on impact, we are your trusted partner in navigating change and staying ahead in a competitive world.

Trusted by Global Industry Leaders

Our clients include some of the world’s most influential organisations, spanning a diverse range of industries. These brands turn to The Future Factory for bespoke leadership development and transformative training that drives real, measurable impact.

Join our growing network of innovators and disruptors. Let’s work together to unlock the full potential of your organisation.

Bespoke Training Built Around Your Organisation

We design and deliver fully customised training programmes tailored to your organisation’s unique challenges and strategic goals. Our expert-led learning experiences develop the leadership, operational, and innovation capabilities needed to drive transformation and measurable impact. Whether delivered on-site, virtually, or through blended learning, our programmes ensure your teams gain practical, business-ready skills that elevate performance and accelerate growth.

-

Unlock new growth opportunities through cutting-edge frameworks and strategies that drive innovation, fuel creativity, and position your business as a market leader.

-

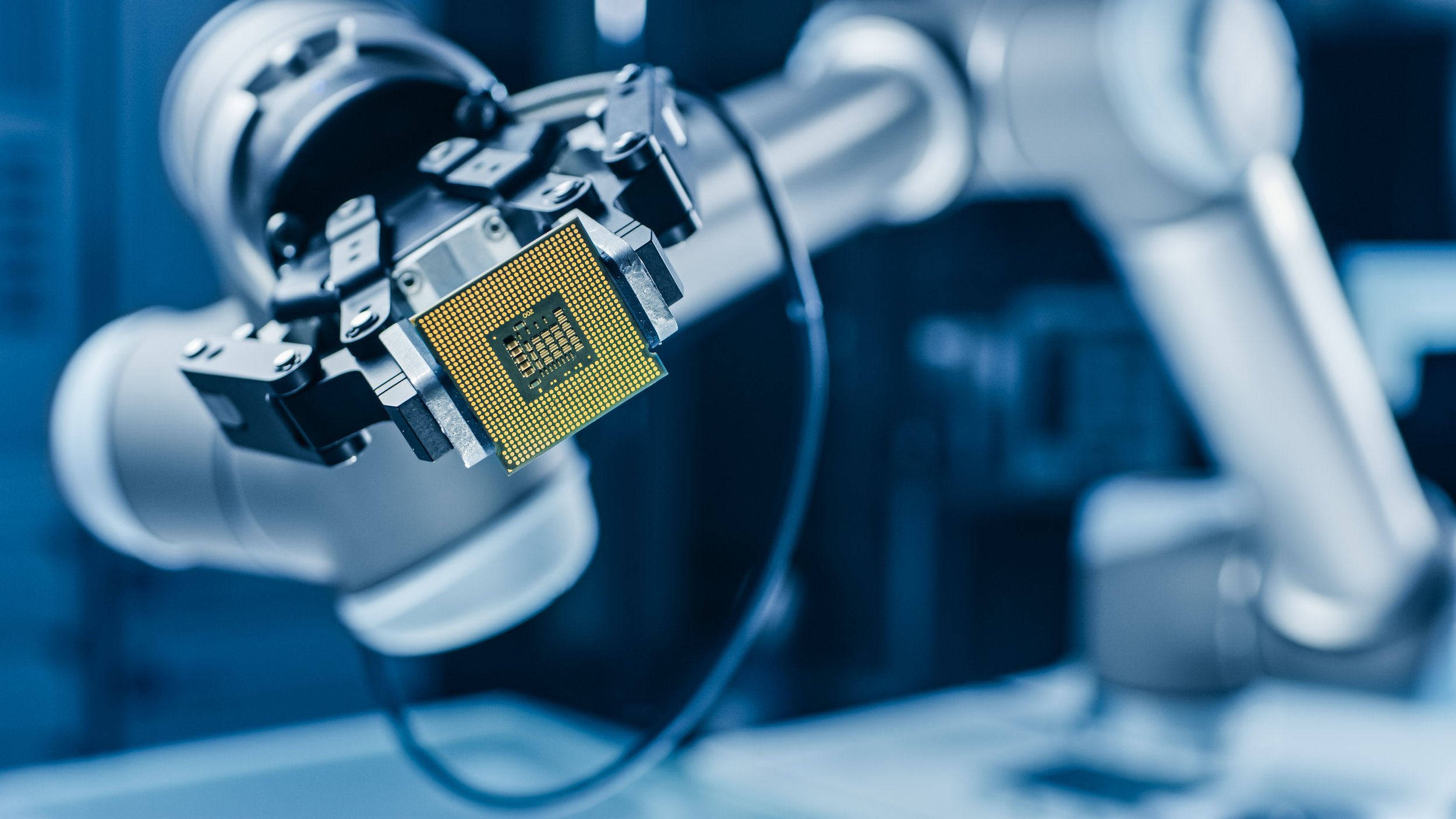

Harness the power of artificial intelligence and machine learning to optimize processes, enhance decision-making, and create future-ready solutions.

-

Build robust data strategies and leverage advanced analytics to uncover insights, streamline operations, and propel your organization into the data-driven future.

-

Develop visionary leaders with the skills to navigate complexity, drive organizational success, and inspire high-performing teams.

-

Enhance operational efficiency and performance metrics with proven methodologies tailored to achieve measurable and sustainable results.

-

Foster a culture of creativity and problem-solving with human-centered design principles that fuel innovation and create meaningful solutions.

-

Cultivate strong, impactful brands with strategies that align with your vision, engage your audience, and drive long-term value.

-

Streamline workflows, eliminate inefficiencies, and foster a culture of continuous improvement to achieve operational excellence and superior performance.

-

Embrace the future of manufacturing and supply chains with smart technologies, automation, and interconnected systems that define the fourth industrial revolution.

-

Safeguard your organisation against emerging threats with cutting-edge cybersecurity solutions and robust risk management strategies designed to protect data, infrastructure, and operations.