AI is not yet adept at most creative endeavours with the exception of math-based elements such as chord progressions in music. The advent of fast fashion apparel over the last decades requires time compression of the cycle, starting with trend-spotting, designer prototyping, scale production and ultimate arrival in retail stores. Missing a trend by a few weeks can result in stacks of unsold merchandise to be marked down. Inditex, one of the world's largest fashion retailers and parent company of Zara, leverages assets that other competitors lack - physical Zara stores: 2,238 of them in 96 countries, each receiving shipments of prototypes and new items twice a week.

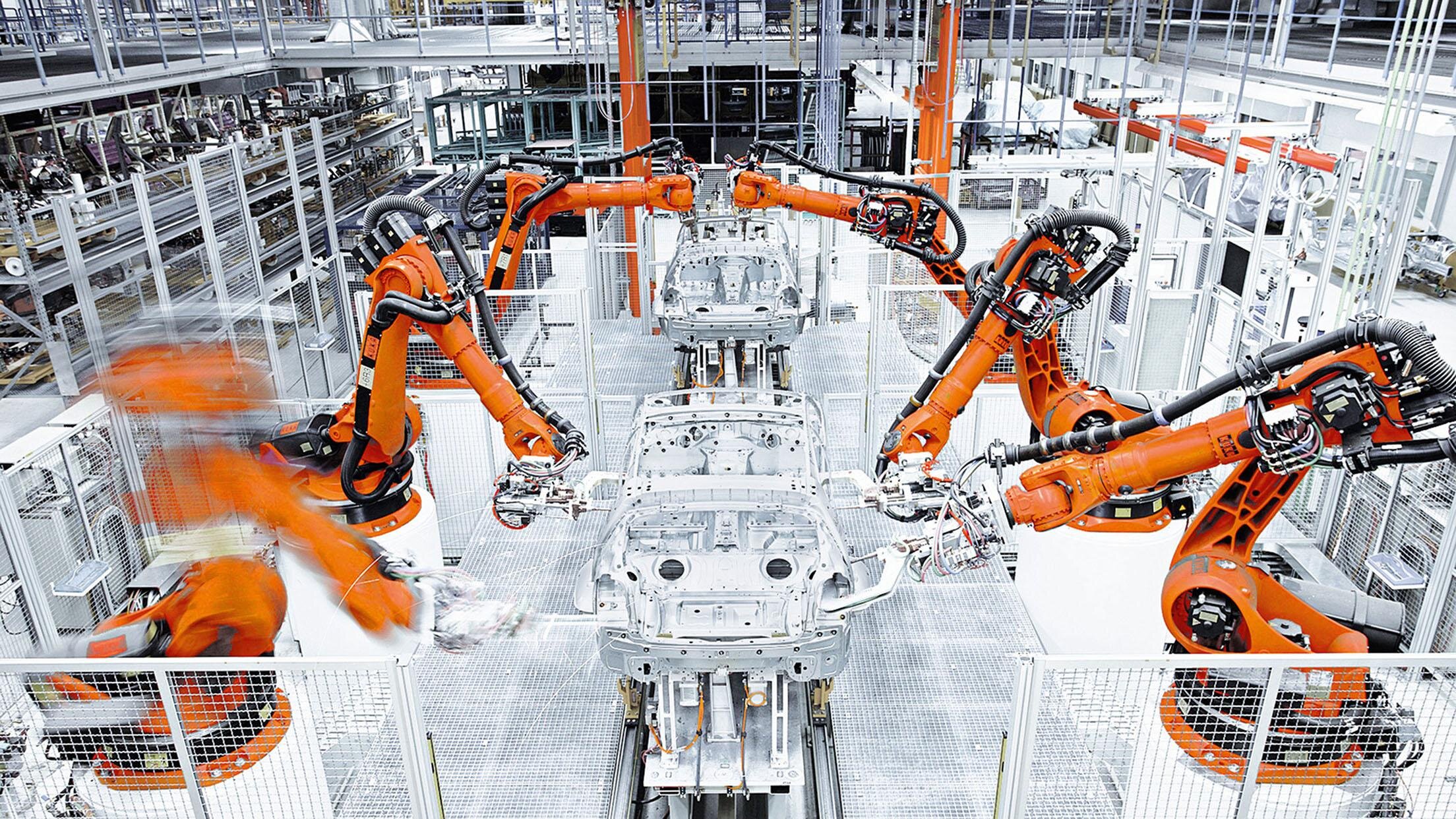

Inditex has a 860,000-square-foot campus which houses 10 different factories; all of these manufacture Zara's most fashion-forward items of clothing - apparel that has special features such as pleating, ruching and insets. All factories sit next to the distribution centres and are connected by a network of underground tunnels that transport clothing on high-speed rails. Inditex has an innovation unit, led by former telecoms engineer Alejandro Ferrer and David Alayon. The unit tests ways of improving stock handling, partnering with California-based Fetch Robotics and Intel to test automated stock inventory and optimise matching volume of clothing to the right size boxes.

Store to factory feedback loops

Inditex sends prototypes to select stores around the world which they know are harbinger locations - places where trendsetting urban super-consumers shop. These customers are invited in to try on hot fashion that is not yet in full scale production. Feedback is collected and transmitted via the web to the factory where refinements and scaling up production plans are made. Inditex knows that local fashionistas will give them the final opinions to produce apparel that clicks with other consumers.

Inditex focuses on location intelligence, ultrasound tech used to track footfall in stores. This intelligence allows apps to switch to instore mode when a person enters a store, so the customer can locate products and receive offers. It also provides data about clothing that is by-passed, where customers linger and which items they actually buy. The firm has also formed development partnerships with technology companies like Jetlore, which uses AI to predict consumer behaviour, and Spanish big data start-up El Arte de Medir. All data finds its way back to the factory floor in Spain. The result is a connected system that ensures retail front line data is transmitted in real time to the factory floor. Inditex combines the best human designers to create the fashion and integrates factory-meets-retail tech to deliver fast, at a good price, giving customers precisely what they want.

About the author

Brian Byrne is a trend forecaster, futurist and business war gamer who advises global corporations and speaks at major conferences worldwide. His team analyses mega-trends, emerging tech and consumer insights to design future scenarios so that clients can determine where to play and how to win. He teaches a “Future of Work” module at York Schulich international eMBA which hosts senior executives from European corporations and governments.